Development of the IIoT ecosystem Netilion

Pilot project in cooperation with the Salzgitter Flachstahl GmbH

A close cooperation between Endress+Hauser and the Salzgitter Flachstahl GmbH is taking place since March 2017 focusing on the development of the IIoT ecosystem Netilion. Since then the installation has been in use and is, in cooperation with the head of maintenance, continuously tested and developed. The aim: increase plant availability!

Results

-

The Netilion IIoT ecosystem was successfully implemented in the continuous pickling line 2 at Salzgitter Flashstahl GmbH and has been constantly evolving ever since.

-

Plant engineers don't have to use the application on a daily operative basis. Instead, they check the changes and the given regular feedback for improvement.

-

In the future, the Netilion IIoT ecosystem shall simplify and ease maintenance tasks and increase plant availability.

The challenge

At the continuous pickling line No. 2, approx. 103 measuring points of Endress + Hauser operate on an approx. 330 m long line. The challenge of an IIoT solution here is to enable a quick overview of the installed base, to provide accurate health status and thus ease work for the maintenance staff from wherever.

The IIoT solution should be simple to install and easy data readout. Ideally the maintenance technician before deployments gets information on location, best solution, required tools, etc.

Realization

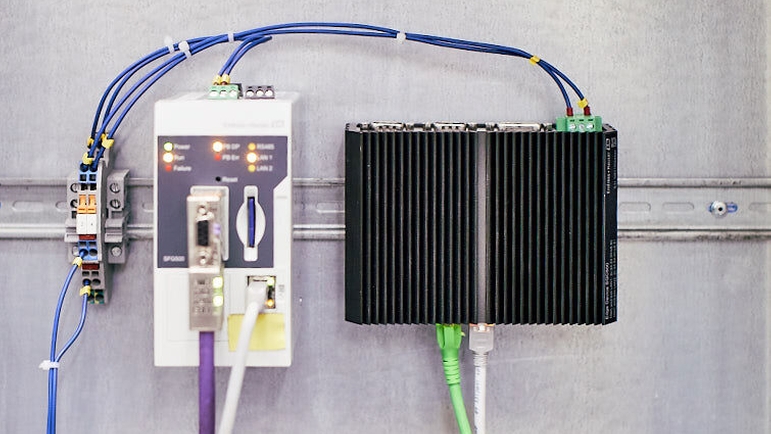

The Ethernet/PROFIBUS Gateway SFG500 and an Edge Device were installed to connect to the Internet into the PROFIBUS network. Both the Gateway and Edge Device provide the connectivity between IT and OT, and scan the entire plant for measuring devices, even from different suppliers.

The Netilion Analytics application generates a digital twin of each scanned device. As Endress+Hauser has been in charge for almost 20 years, the device data is complemented with data of 40 million data records.

Netilion Analytics gives an overview of all devices in the plant.

Netilion Health enables the users to see the health status of the assets and also provide direct access to profound knowledge on their maintenance and care

Netilion Library allows files and documents to be saved for specific measuring instruments, which are then available for all users in the Netilion IIoT ecosystem.

Components of the Netilion ecosystem

Netilion Analytics

Netilion Health

Netilion Library

Edge Device

Fieldgate SFG500